Featured Categories

Heat Shrink FAQ Reference Guide

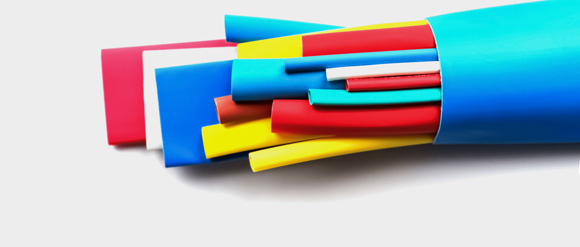

Q: What is Heat Shrink?

A: Heat shrink tubing is shrinkable plastic tubing primarily used to insulate wires. The tight seal, created by shrinking the insulating plastic, provides long-term abrasion resistance and protection from environmental harm. By creating an additional layer of protection for wires, heat shrink ensures the longevity of the wiring work and the safety of the user. Heat shrink is ideal for all stranded and solid wire conductors, connections, joints and terminals commonly found in electrical work. Other names for heat shrink include: shrink wrap, shrink band, shrink tubing, heat shrink sleeve, heat shrink sleeves, and heat shrinkable tubing.

Q: What is Heat Shrink Tubing used for?

A: Though a recent innovation, heat shrink is widely used in the wiring profession today, specifically in the electrical wiring of automobiles for construction, military and aviation, as well as spacecraft. Heat shrink is ideal for insulating in tight spaces, such as the narrow confines of modern computers, audio/visual equipment, as well as common domestic and industrial appliances. Heat shrink tubing streamlines electrical insulation, wire bundling, color coding, cable bundling, corrosion protection, strain relief and weather/moisture sealing for wires and cables. Heat shrink tube protects against the fire hazard created by open or unprotected wiring.

Q: What Other Heat Shrink Accessories and Tools Can I Buy?

A: Heat Shrink Kits, Heat Shrink Butt Splice Connectors & Terminals, Branded Custom Printed Heat Shrink Tubing, Label & Heat Shrink Printers, Heat Guns & Tubing Cutters, Cable Ties

Q: How Do I Order on Buyheatshrink?

A: The Customer Service department at BuyHeatShrink.com is open Monday - Friday from 8:00 AM - 5:30 PM (EST). Online orders may be placed 24 hours a day, 7 days a week. We have a $10 minimum order for orders placed on our website. We accept online payment with VISA, Mastercard, American Express and Paypal—corporate and government credit cards welcome. For Money Order payments, we will ship product upon receipt of payment. Customers wishing to open a corporate account must first get approved for terms with us. Do this by selecting "Money Order" as the method of payment and faxing your credit references to 888-619-2010. In order to get set up on payment terms (i.e. Net 30) with us, we require a minimum first time purchase of $200. This helps us cover the costs of setting up your account, establishing credit, etc. (note - If you wish to purchase less than $200 from us, you can still do so with a credit card (the minimum for credit card purchases is $10.)

Q: Why BuyHeatShrink?

A: At BuyHeatShrink.com we specialize in sales to distributors and medium to large OEM's (Original Equipment Manufacturers), and we will happily customize your order, whether it is custom cut lengths, barcode labels or blind drop shipping—just let us know.

We routinely work with electrical distributors for car, truck, boat and airplane manufacturers. Many of our products meet the stringent requirements of UL (e.g. 94V0, VW-1), Military specifications (e.g. Mil-I-23053 for heat shrink tubing, and Mil-DTL-81914 for aerospace convoluted tubing), and many automotive specifications (e.g. Delphi Packard M-2170, Ford ESF-M4D 423-A, and General Motors GMP.PA6.003, just to name a few).